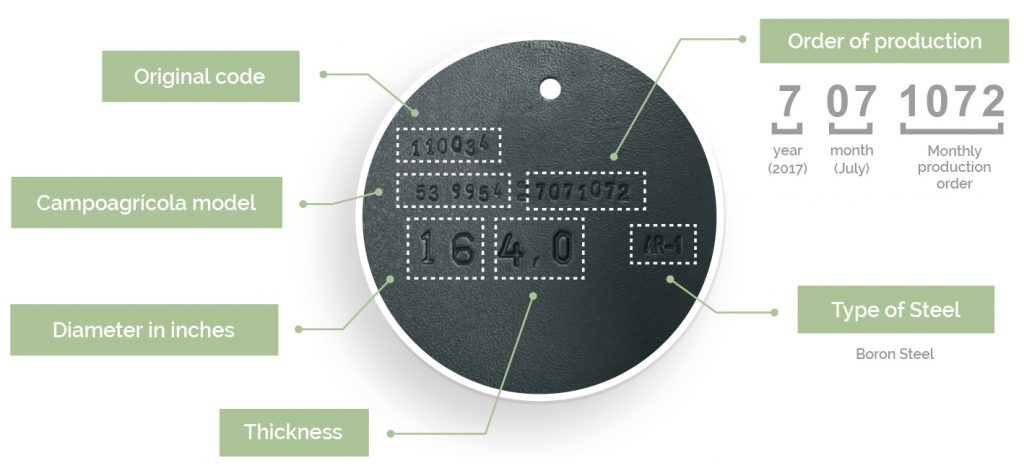

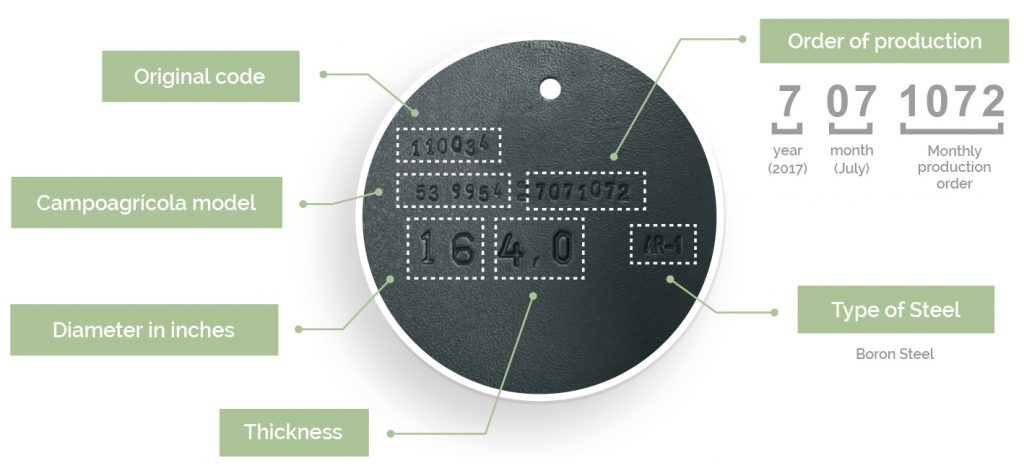

La The traceability of CAMPOAGRÍCOLA discs and points allows us to know on what date the product has been manufactured, the monthly production order, its diameter, its thickness, the original code and the internal model.

La The traceability of CAMPOAGRÍCOLA discs and points allows us to know on what date the product has been manufactured, the monthly production order, its diameter, its thickness, the original code and the internal model.

From CAMPOAGRICOLA we have designed a traceability for the chisel assemblies, based on production orders by orders. In each order we mark all the components used and their internal traceability.

The entire process is recorded and we can check subsequent incidents. This system, which was applied to exports, will be implemented for all production from August 2020.

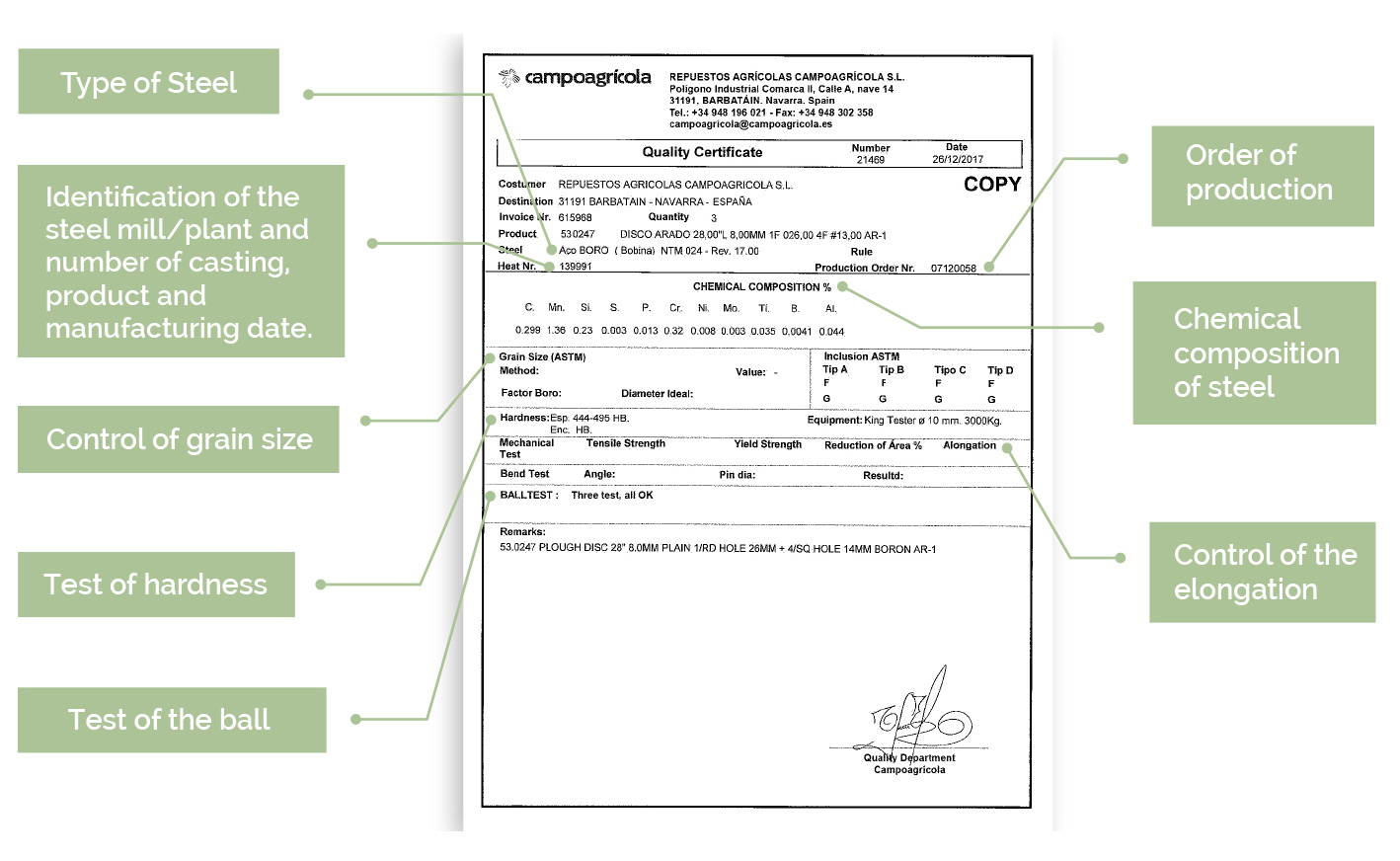

In CAMPOAGRÍCOLA we control the quality of our products: First of all in the approval of suppliers, controlling the manufacturing processes, heat treatments, internal traceability and finished product test; Secondly, we control the final product: dimension, hardness, assembly process, finishes and packaging.

9 am - 8 pm

31191 Barbatain Navarra España

campoagricola@campoagricola.es